Vancouver, BC – November 9-11, 2018

ESSENTIAL ELEMENTS OF COMPOUNDED STERILE PREPARATIONS

Testimonials | Learning Objectives

This course includes a home study component ($700 value) that serves as a prerequisite to the live activity. To review the full activity description of the home study component click here. To access your home study, click on the Register tab above, choose the specific location & date that you are enrolled in and then click the “Take Course” button in the Course Summary box on the "Overview" tab.

This practice-based activity features a series of sixteen workstations. Participants will work in small groups, moving from workstation-to-workstation every hour. Live competency assessment reports will be completed by facilitators throughout the duration of this live event, providing immediate performance-related feedback to participants. Prior to the workstation rotations, participants will engage in a live event orientation. This orientation includes a gowning demonstration, followed by a practical orientation that explores a unique quality management system – System P (Personnel, Property, Procedure, Process, Preparation, and Patient). This is followed by an aseptic technique practical skills assessment which assists facilitators in the grouping of participants in accordance to their respective skill level. Once participants are appropriately assigned to their respective groups, workstation rotations will commence. Workstations, addressing non-hazardous and hazardous drug compounding, include:

- Preparation of four compounded sterile medications while working in a current USP Chapter <797> compliant clean room environment featuring a garbing room.

- Four simulated sterile preparations with a focus on aseptic techniques.

- Manipulation of a broad range of reusable and disposable technology including closed system transfer devices for use during hazardous drug compounding.

- Disinfection procedures.

- Media-fill challenge test.

- Documentation of a master formulation record template.

- Creation of a facility design and its related workflow.

- Risk management assessment and process development.

- Verification protocol development.

- Observational auditing.

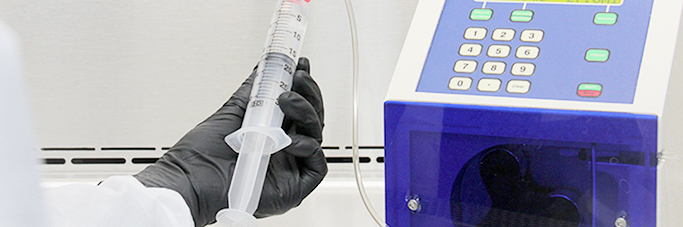

- Automated compounding device training which features a peristaltic pump.

Participants will gain valuable experience in handling modern technology for today’s compounding pharmacy practice including electromechanical equipment, reusable and disposable devices, testing technologies used for viable surface sampling, non-viable and viable particulate monitoring, preparation sterility and endotoxin testing, wet and dry heat sterilization methods, depyrogenation, incubation, and SEC/PEC HEPA filter integrity and airflow dynamics. Positive and negative control technology is also highlighted and incorporates the use of indicators and integrators.

Participants will undergo visual observation and performance assessments throughout the activity, as they perfect their aseptic techniques of hand washing, garbing, moving within and between ISO class environments, and technology manipulation which includes end-stage filtration and filter integrity testing. Throughout this live event, time allotments have been built into the schedule for participant question and answer periods. The activity concludes with a brief summary and closing remarks presentation.

Testimonials:

![]()

| I always find that the lab component of a class is important and with this course, we realized just how important the hands-on lab skills are. The fact that the practical component is the majority of the course makes it more special and complete. During the course, we had the opportunity to manipulate all equipment with supervision and guidance, giving us more confidence when we use these techniques and equipment in our day-to-day practice. Adequate training clarifies any doubts we may already have, and anything that comes up during the training can be addressed as well. All the teachers are very attentive and everything was perfect! Angelica Vita |

| I have previously completed a non-sterile compounding course given by LP3 Network and had a positive outcome, utilizing much of what I learned in the course in my practice as an outpatient pharmacist. Having recently taken a position in a hospital setting, I decided to build on my basic knowledge of sterile compounding. I chose LP3 Network again because, in my opinion, they are recognized as experts in this facet of pharmacy, and justifiably so. I highly recommend this program to any person who has the desire to excel in their compounding skills, because you can only be one of the best, if you learn from the best. The course provided me with valuable, relevant and applicable information on sterile compounding in the comfort of a beautiful practice site. The combination of expert, highly knowledgeable instructors, the didactic written materials, the hands-on-practical experience in a state-of–the-art lab that reflects a matrix of sterility with sparkling glass and mirrors throughout, provided me with one of the finest programs in my 30+ year career and I came away with having a proactive, rather than reactive approach to the preparation of compounded medications. My confidence has been 'compounded', no pun intended! Pauline A. D’Chiutiis |

| What a wonderful program! I had the opportunity to take the non-sterile compounding course with Ken Speidel, Ken Latta and Mark Filosi two years prior and was shocked that they remembered me. This truly shows that when you take a course through LP3 Network, the instructors take the time to get to know the individuals they are teaching. They use different types of learning throughout the entire program to grab the attention of every type of learner, through lecture, hands-on, and peer education. Without this program I believe that there would be some major gaps in our own instruction and performance in the lab, i.e., checking and rechecking equipment, sterility testing and validating and so on. This program would not be complete without the practical component because it puts all the literature into perspective and the instructors teaching this course are absolutely A1! After taking the Sterile program, I honestly believe that no sterile lab should be compliant without an individual on staff having this training to make sure they fully understand the application of the theoretical knowledge. I can truly say leaving here today I am prepared to practice and teach in a sterile field. Stephanie Armstrong |

| I was truly amazed by the amount of time dedicated to hands-on, practical skills during the Sterile compounding course. As a device specialist, I really appreciated the attention given to the proper use of lab equipment and devices, including laminar flow hoods, air-samplers, testing technologies for viable surface sampling, closed system transfer devices, and automated volumetric pumps. The fact that LP3 Network’s state-of-the-art facility is stocked with the latest compounding technologies was a huge bonus – especially for someone in my field! Not only did the instructors demonstrate the appropriate techniques for handling equipment and compounded preparations, but also discussed how these techniques were relevant to personnel safety and best practices, in order to prepare safe and effective compounded medications for a diverse patient population. Alexander Hanna

|

Intended audience

Learning Objectives

FOR PHARMACISTS:

- Argue in defense of the parameters of a quality management system engaged in sterile compounding for non-hazardous and hazardous drugs.

- Support standards of practice and scientific principles applicable to sterile compounding for non-hazardous and hazardous-drugs.

- Defend the application of risk management that addresses sterile compounding and the safe handling and management of non-hazardous and hazardous drugs.

- Propose verification procedures that satisfy the scientific principles of efficacy, reliability, and validity for numerous operational and functional parameters within a sterile compounding practice.

- Defend a functional and operational facility workflow design schematic for a sterile compounding facility, in compliance with standards of practice related to the safe handling and management of non-hazardous and hazardous drugs.

- Practice gowning, technology transferring, entering, and exiting protocols within ISO class controlled environments.

- Practice a series of aseptic techniques in consideration of critical first air, touch- and cross-contamination.

- Practice aseptic techniques used to compound sterile preparations in an ISO class environment and in compliance with the United States Pharmacopeia (USP) and related standards of practice.

- Practice aseptic techniques specific to hazardous drug compounding utilizing closed system transfer devices.

- Defend the use of monitoring- and testing-related technologies used in a sterile compounding practice.

- Assess the use and application of indicators and integrators that serve as controls during environmental monitoring, incubation, terminal sterilization, and depyrogenation protocols.

- Manage the use of technologies used for microbial air and surface sampling, non-viable particulate monitoring, filter integrity testing, preparation sterility and endotoxin testing, terminal sterilization, depyrogenation, disinfection, incubation, and SEC/C-SEC/PEC/C-PEC HEPA filter integrity and airflow dynamics.

- Demonstrate a robust media-fill challenge test in compliance with USP standards of practice.

- Manage environmental-, human performance-, and preparation-related audits in compliance with USP and related standards of practice.

- Assess regulatory-, preparatory-, and clinical-related risk in a sterile compounding practice.

- Demonstrate the use and functional parameters of an Automated Compounding Device (ACD) used in a sterile compounding practice.

- Design a master formulation record that consists of pre- and post-qualification requirements related to facility, technology, and personnel, preparation testing, end-stage filtration, terminal sterilization, inspection, beyond-use dating, packaging, labeling, and shipping.

FOR TECHNICIANS:

- Support the parameters of a quality management system employed by a pharmacist-in-charge in a non-hazardous and hazardous drug sterile compounding practice.

- Support standards of practice and scientific principles advocated in a sterile compounding practice specialized in non-hazardous and/or hazardous drug compounding.

- Evaluate, as a responsibility of all personnel, the application of risk management that addresses sterile compounding and the safe handling and management of non-hazardous and hazardous drugs.

- Assess verification procedures that are routinely followed and that satisfy the scientific principles of efficacy, reliability, and validity for numerous operational and functional parameters, should recommendations for change be warranted.

- Assess functional and operational facility workflow design schematics related to the safe handling and management of non-hazardous and hazardous drugs, should recommendations for change be warranted.

- Practice gowning, technology transferring, entering, and exiting protocols within ISO class controlled environments.

- Practice a series of aseptic techniques in consideration of critical first air, touch- and cross-contamination.

- Practice aseptic techniques used to compound sterile preparations in an ISO class environment and in compliance with the United States Pharmacopeia (USP) and related standards of practice.

- Practice aseptic techniques specific to hazardous drug compounding utilizing closed system transfer devices.

- Manage monitoring- and testing-related technologies used in a sterile compounding practice.

- Support the routine use of indicators and integrators through their application in environmental monitoring, incubation, terminal sterilization, and depyrogenation protocols.

- Support the use of technologies through their application in microbial air and surface sampling, non-viable particulate monitoring, filter integrity testing, preparation sterility and endotoxin testing, terminal sterilization, depyrogenation, disinfection, incubation, and SEC/C-SEC/PEC/C-PEC HEPA filter integrity and airflow dynamics.

- Demonstrate a robust media-fill challenge test in compliance with USP standards of practice.

- Plan to engage in environmental-, human performance-, and preparation-related audits to demonstrate compliance with USP and related standards of practice.

- Demonstrate the use and functional parameters of an Automated Compounding Device (ACD) used in a sterile compounding practice.

- Support the use of a master formulation record to demonstrate required compliance with standards of practice that consists of pre- and post-qualification requirements related to facility, technology, personnel, preparation testing, end-stage filtration, terminal sterilization, inspection, beyond-use dating, packaging, labeling, and shipping.

FINANCIAL SUPPORT:

An unrestricted educational grant has been provided by MEDISCA Inc.

COPYRIGHT:

The live activity workbook is copyright © 2016 LP3 Network.

Travel information

The training will take place at the LP3 Network Facility.

Getting to the Training Facility: We are pleased to offer shuttle service to and from the hotel and the training facility. Please meet the LP3 Network team in the lobby of the hotel at 6:45am sharp for transportation to the training facility. The LP3 Network team assumes that all participants will use the shuttle service provided, if staying at the hotel. It is important to advise us if you will not use this service.

The preferred hotel accommodation is the Hilton Vancouver Airport.

For reservations, please call 604-233-3990 or toll free at 1-800-445-8667.

Based on Availability. Payment for hotel accommodations is at the expense of the activity participant.

Facilitators will be accounced closer to the activity start date – please check back soon!

Note: Facilitators are subject to change.

Editors

NEIL COHEN, BSc NEIL COHEN, BScCE Program Developer Disclosure: None |  |

CONTRIBUTORS:

Total CPE Credits (home study and live activity): 50 CPE Hours = 5.0 CEUs

Joint Providership Status (CPE Consultants, LLC / LP3 Network)

Home study activity type: Knowledge-based

Home study UAN: 0864-9999-18-047-H07-P/T for pharmacists and technicians

Home study CPE credits: 30 CPE hours = 3.0 CEUs

Release date: April 20, 2018

Expiration date: April 20, 2021

Live activity type: Practice-based

Live activity UAN: 0864-9999-18-048-L07-P/T for pharmacists and technicians

Live activity CPE credits: 20 CPE Hours = 2.0 CEUs

Release date: June 22, 2018

Expiration date: June 22, 2021

To receive CPE credits for the home study, participants must complete a learning assessment with a score of 70% and submit a completed evaluation. To receive CPE credits for the live activity, participants must demonstrate full and satisfactory participation, and submit a completed evaluation.

| CPE Consultants, LLC is accredited by the Accreditation Council for Pharmacy Education as a provider of continuing pharmacy education. |

CANCELLATION AND REFUND POLICY:

A written request must be sent to LP3 Network requesting “Cancellation without Transfer” to an alternate live activity date. If cancellation occurs at greater than or equal to 31 days from the live activity date, then the registrant will receive a 75% refund; 15-30 days a 50% refund; and less than or equal to 14 days no refund.

TRANSFER POLICY:

The transfer policy is only in effect if requested greater than or equal to 14 days prior to the original live activity date. Failure to submit the “Transfer Request” at least 14 days prior to the original live activity date will default to the “Cancellation and Refund Policy”. The transfer policy can only be applied one (1) time. Transfer to a new live activity date must be within the current calendar year. Failure to attend the new live activity will result in no refund and will no longer be transferable. Confirmation of the new activity date is subject to approval by LP3 Network based on the number of available seats within the selected live activity. There are no refunds, returns, or transfers upon purchase of the home study.

Facebook

Facebook X

X LinkedIn

LinkedIn Forward

Forward