Aventura, FL – August 26-28, 2016

ESSENTIAL ELEMENTS OF PRESCRIPTION STERILE COMPOUNDING

Accreditation | Learning Objectives | Contributors & Facilitators | Event Date |

Hotel Location | Current Promotion | Purchase Information

This course includes a home study component ($825 value) that serves as a prerequisite to the live activity. To review the full activity description of the home study component click here.

This practice-based activity features a series of sixteen workstations. Participants will work in small groups, moving from workstation-to-workstation every hour. Live competency assessment reports will be completed by facilitators throughout the duration of this live event, providing immediate performance-related feedback to participants. Prior to the workstation rotations, participants will engage in a live event orientation. This orientation includes a gowning demonstration, followed by a practical orientation that explores a unique quality management system – System P (Personnel, Property, Procedure, Process, Preparation, and Patient). This is followed by an aseptic technique practical skills assessment which assists facilitators in the grouping of participants in accordance to their respective skill level. Once participants are appropriately assigned to their respective groups, workstation rotations will commence. Workstations, addressing non-hazardous and hazardous drug compounding, include:

- Preparation of four compounded sterile medications while working in a current USP Chapter <797> compliant clean room environment featuring a garbing room.

- Four simulated sterile preparations with a focus on aseptic techniques.

- Manipulation of a broad range of reusable and disposable technology including closed system transfer devices for use during hazardous drug compounding.

- Disinfection procedures.

- Media-fill challenge test.

- Documentation of a master formulation record template.

- Creation of a facility design and its related workflow.

- Risk management assessment and process development.

- Verification protocol development.

- Observational auditing.

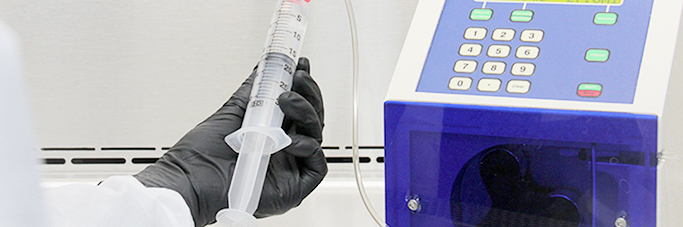

- Automated compounding device training which features a peristaltic pump.

Participants will gain valuable experience in handling modern technology for today’s compounding pharmacy practice including electromechanical equipment, reusable and disposable devices, testing technologies used for viable surface sampling, non-viable and viable particulate monitoring, preparation sterility and endotoxin testing, wet and dry heat sterilization methods, depyrogenation, incubation, and SEC/PEC HEPA filter integrity and airflow dynamics. Positive and negative control technology is also highlighted and incorporates the use of indicators and integrators.

Participants will undergo visual observation and performance assessments throughout the activity, as they perfect their aseptic techniques of hand washing, garbing, moving within and between ISO class environments, and technology manipulation which includes end-stage filtration and filter integrity testing. Throughout this live event, time allotments have been built into the schedule for participant question and answer periods. The activity concludes with a brief summary and closing remarks presentation.

Intended audience

Learning Objectives

FOR PHARMACISTS:

- Argue in defense of the parameters of a quality management system engaged in sterile compounding for non-hazardous and hazardous drugs.

- Support standards of practice and scientific principles applicable to sterile compounding for non-hazardous and hazardous-drugs.

- Defend the application of risk management that addresses sterile compounding and the safe handling and management of non-hazardous and hazardous drugs.

- Propose verification procedures that satisfy the scientific principles of efficacy, reliability, and validity for numerous operational and functional parameters within a sterile compounding practice.

- Defend a functional and operational facility workflow design schematic for a sterile compounding facility, in compliance with standards of practice related to the safe handling and management of non-hazardous and hazardous drugs.

- Practice gowning, technology transferring, entering, and exiting protocols within ISO class controlled environments.

- Practice a series of aseptic techniques in consideration of critical first air, touch- and cross-contamination.

- Practice aseptic techniques used to compound sterile preparations in an ISO class environment and in compliance with the United States Pharmacopeia (USP) and related standards of practice.

- Practice aseptic techniques specific to hazardous drug compounding utilizing closed system transfer devices.

- Defend the use of monitoring- and testing-related technologies used in a sterile compounding practice.

- Assess the use and application of indicators and integrators that serve as controls during environmental monitoring, incubation, terminal sterilization, and depyrogenation protocols.

- Manage the use of technologies used for microbial air and surface sampling, non-viable particulate monitoring, filter integrity testing, preparation sterility and endotoxin testing, terminal sterilization, depyrogenation, disinfection, incubation, and SEC/C-SEC/PEC/C-PEC HEPA filter integrity and airflow dynamics.

- Demonstrate a robust media-fill challenge test in compliance with USP standards of practice.

- Manage environmental-, human performance-, and preparation-related audits in compliance with USP and related standards of practice.

- Assess regulatory-, preparatory-, and clinical-related risk in a sterile compounding practice.

- Demonstrate the use and functional parameters of an Automated Compounding Device (ACD) used in a sterile compounding practice.

- Design a master formulation record that consists of pre- and post-qualification requirements related to facility, technology, and personnel, preparation testing, end-stage filtration, terminal sterilization, inspection, beyond-use dating, packaging, labeling, and shipping.

FOR TECHNICIANS:

- Support the parameters of a quality management system employed by a pharmacist-in-charge in a non-hazardous and hazardous drug sterile compounding practice.

- Support standards of practice and scientific principles advocated in a sterile compounding practice specialized in non-hazardous and/or hazardous drug compounding.

- Evaluate, as a responsibility of all personnel, the application of risk management that addresses sterile compounding and the safe handling and management of non-hazardous and hazardous drugs.

- Assess verification procedures that are routinely followed and that satisfy the scientific principles of efficacy, reliability, and validity for numerous operational and functional parameters, should recommendations for change be warranted.

- Assess functional and operational facility workflow design schematics related to the safe handling and management of non-hazardous and hazardous drugs, should recommendations for change be warranted.

- Practice gowning, technology transferring, entering, and exiting protocols within ISO class controlled environments.

- Practice a series of aseptic techniques in consideration of critical first air, touch- and cross-contamination.

- Practice aseptic techniques used to compound sterile preparations in an ISO class environment and in compliance with the United States Pharmacopeia (USP) and related standards of practice.

- Practice aseptic techniques specific to hazardous drug compounding utilizing closed system transfer devices.

- Manage monitoring- and testing-related technologies used in a sterile compounding practice.

- Support the routine use of indicators and integrators through their application in environmental monitoring, incubation, terminal sterilization, and depyrogenation protocols.

- Support the use of technologies through their application in microbial air and surface sampling, non-viable particulate monitoring, filter integrity testing, preparation sterility and endotoxin testing, terminal sterilization, depyrogenation, disinfection, incubation, and SEC/C-SEC/PEC/C-PEC HEPA filter integrity and airflow dynamics.

- Demonstrate a robust media-fill challenge test in compliance with USP standards of practice.

- Plan to engage in environmental-, human performance-, and preparation-related audits to demonstrate compliance with USP and related standards of practice.

- Demonstrate the use and functional parameters of an Automated Compounding Device (ACD) used in a sterile compounding practice.

- Support the use of a master formulation record to demonstrate required compliance with standards of practice that consists of pre- and post-qualification requirements related to facility, technology, personnel, preparation testing, end-stage filtration, terminal sterilization, inspection, beyond-use dating, packaging, labeling, and shipping.

An unrestricted educational grant has been provided by MEDISCA Inc.

Total CPE Credits (home study and live activity): 50 CPE Hours = 5.0 CEUs

Joint Accreditation Status (University of Florida College of Pharmacy / LP3 Network)

Live activity type: Practice-based

UAN: 0012-9999-16-007-L04-P/T for pharmacists and technicians

To receive CPE credits for the home study, participants must complete a learning assessment with a score of 70% and submit a completed evaluation to the University of Florida College of Pharmacy. To receive CPE credits for the live activity, participants must demonstrate full and satisfactory participation, and submit a completed evaluation to the University of Florida College of Pharmacy.

Participants registered in the United States can obtain a statement of credit from their NABP e-profile. The University of Florida College of Pharmacy will report CPE credits to the CPE Monitor. Participants registered other than in the United States will receive a statement of credit by mail.

International participants should verify with their respective governing board for accreditation equivalency.

Price

A written request must be sent to LP3 Network requesting “Cancellation without Transfer” to an alternate live activity date. If cancellation occurs at greater than or equal to 31 days from the live activity date, then the registrant will receive a 75% refund; 15-30 days a 50% refund; and less than or equal to 14 days no refund. There are no refunds, returns, or transfers upon purchase of the home study.

TRANSFER POLICY:

The transfer policy is only in effect if requested greater than or equal to 14 days prior to the original live activity date. Failure to submit the “Transfer Request” at least 14 days prior to the original live activity date will default to the “Cancellation and Refund Policy”. The transfer policy can only be applied one (1) time. Transfer to a new live activity date must be within the current calendar year. Failure to attend the new live activity will result in no refund and will no longer be transferable. Confirmation of the new activity date is subject to approval by LP3 Network based on the number of available seats within the selected live activity. There are no refunds, returns, or transfers upon purchase of the home study.

CURRENT PROMOTION:

20% Off

Use coupon code 20LP316 upon checkout to receive 20% off this educational training.

Use coupon code 20LP316 upon checkout to receive 20% off this educational training.

PURCHASE INFORMATION:

Don’t see the Add to Cart button? Please try to Log In, Create an Account or Contact Us for help!

Facebook

Facebook X

X LinkedIn

LinkedIn Forward

Forward